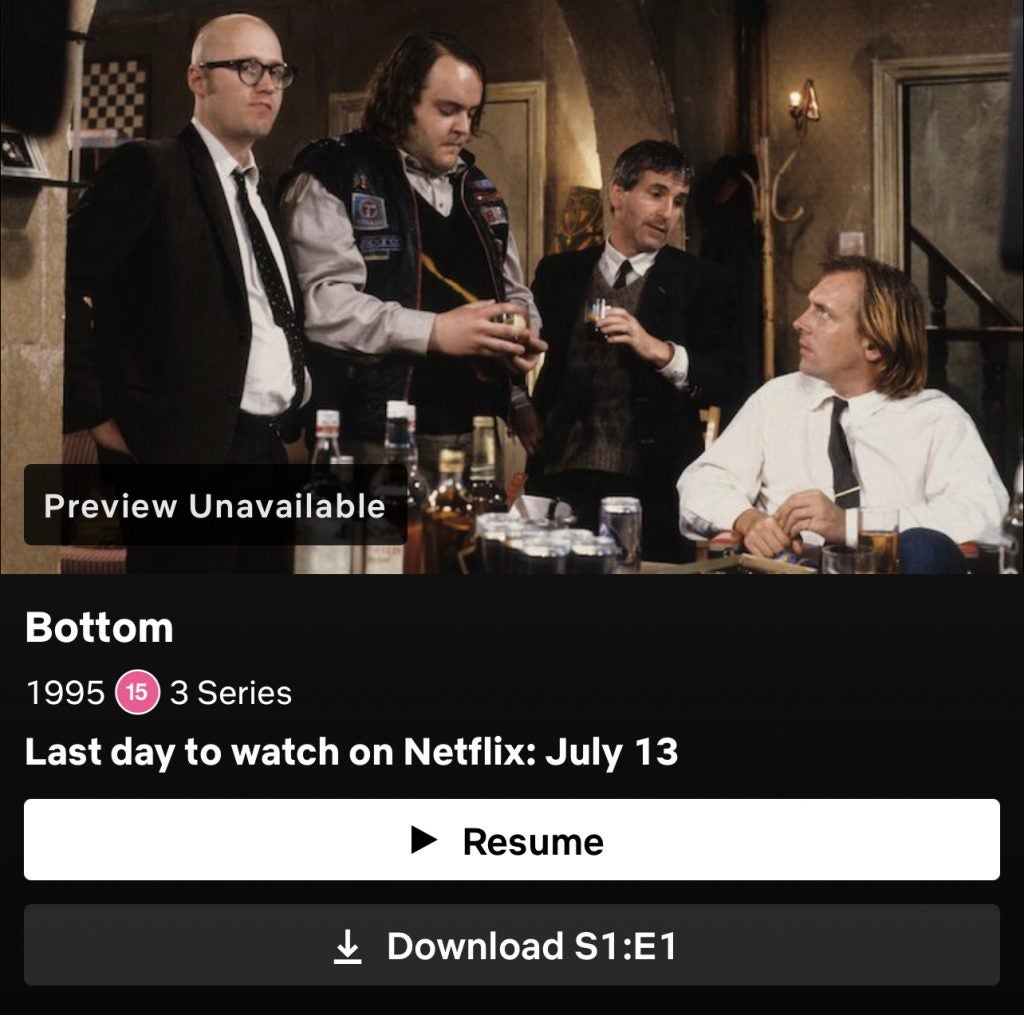

Netflix is losing some of the best British comedy shows ever – here's what's leaving | Trusted Reviews

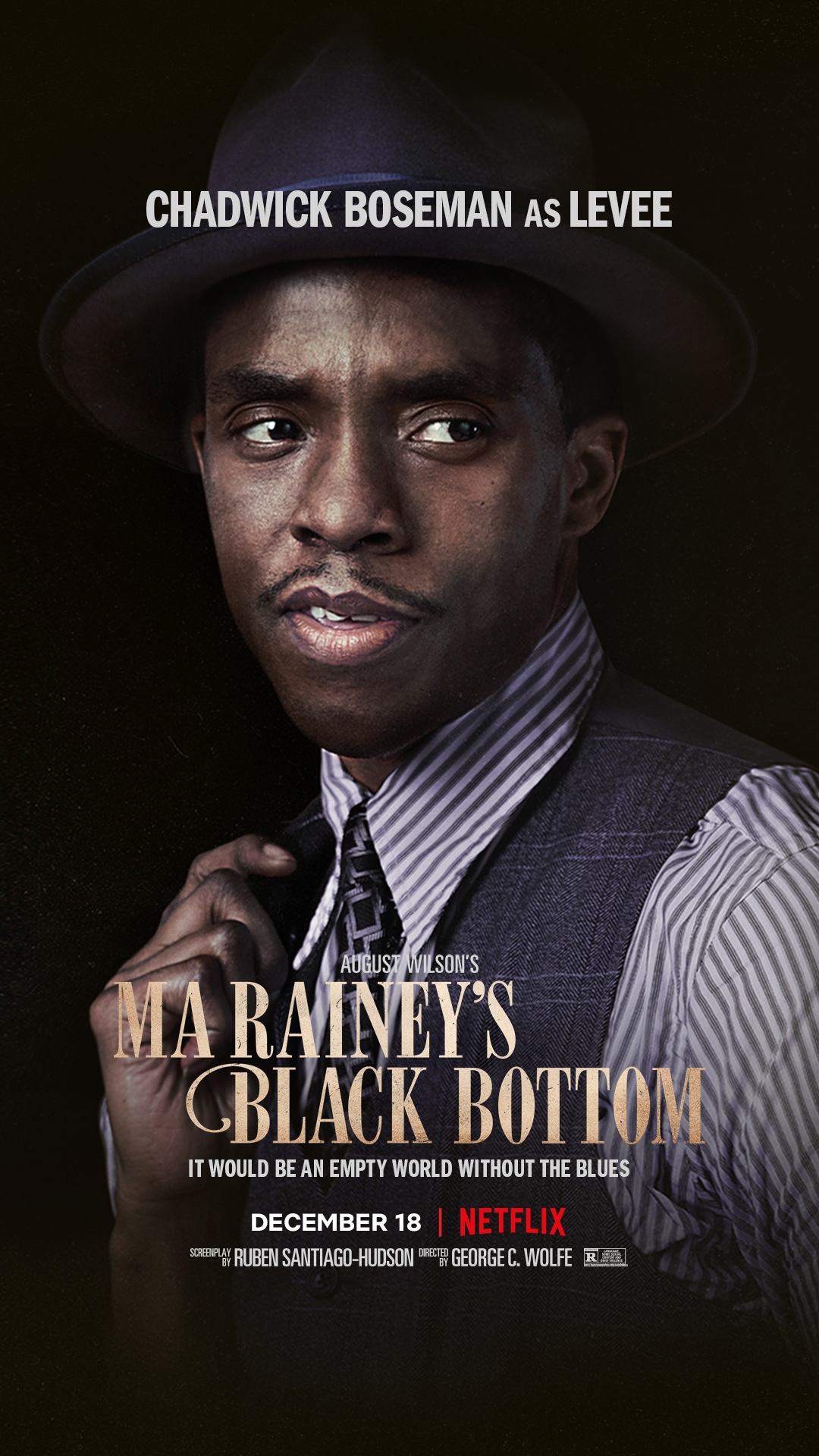

Ma Rainey's Black Bottom (Music from the Netflix Film) | CD Album | Free shipping over £20 | HMV Store

Best series to watch on Netflix February: Here are 10 of the best new series on Netflix UK this month | The Scotsman